Bridging the Future: Sunko Proje Answers Your Top Bridge Design Questions

At Sunko Proje A.Ş., we believe that exceptional bridge design is rooted in innovation, precision, and a deep understanding of engineering principles. As leaders in the field, we’re often asked about the complexities and challenges involved in bridge design. Below, we’ve answered some of the most frequently asked questions to give you insight into our approach and showcase our expertise.

1. How does Sunko Proje approach load distribution in multi-span cable-stayed bridges?

Load distribution is critical in ensuring the longevity and safety of a bridge. At Sunko Proje A.Ş., we use advanced Finite Element Analysis (FEA) to model the structure, taking into account the stiffness of the deck, the tension in the cables, and the position of the pylons. By meticulously analyzing these factors, we ensure that the forces are evenly distributed, preventing localized overstressing and contributing to a durable, resilient bridge design.

2. What materials does Sunko Proje choose for different bridge components, and why?

Material selection is a fundamental aspect of our design process. For the bridge deck, we often choose high-strength concrete or steel due to their ability to handle compressive and tensile forces. Cables, which play a crucial role in supporting the deck, are selected for their high tensile strength and corrosion resistance, typically using galvanized steel or advanced steel alloys. The pylons, bearing significant compressive forces, are usually constructed from reinforced concrete or steel. These choices are made not only for structural integrity but also to ensure long-term durability and cost-efficiency.

3. How does Sunko Proje tackle challenging soil conditions when designing bridge foundations?

When faced with challenging soil conditions, Sunko Proje A.Ş. conducts thorough geotechnical investigations to understand soil properties such as bearing capacity and settlement potential. For example, in soft clayey soils, we might design a foundation system using driven steel piles to transfer loads to more stable soil layers, thereby minimizing settlement. Our adaptive approach ensures that even in difficult conditions, our bridges maintain their structural integrity and safety.

4. How does Sunko Proje account for dynamic loads like wind, traffic, and seismic activity in bridge design?

Dynamic loads are time-varying forces that significantly impact bridge design. At Sunko Proje A.Ş., we analyze these loads using comprehensive methods such as wind load analysis for aerodynamic stability, and response spectrum analysis for seismic forces. We integrate features like damping devices and expansion joints to mitigate the effects of wind, traffic, and seismic activity, ensuring the bridge remains safe and stable under dynamic conditions.

5. What steps does Sunko Proje take in Finite Element Analysis (FEA) for bridge design?

FEA is a cornerstone of our design process. We begin by defining the bridge’s geometry and selecting appropriate element types—such as beam, shell, or solid elements—before applying boundary conditions and loads. Critical to our process is the accurate representation of connections like bearings and joints, which ensures the model’s precision. Through iterative refinement and sensitivity analysis, we achieve highly accurate results that guide our engineering decisions.

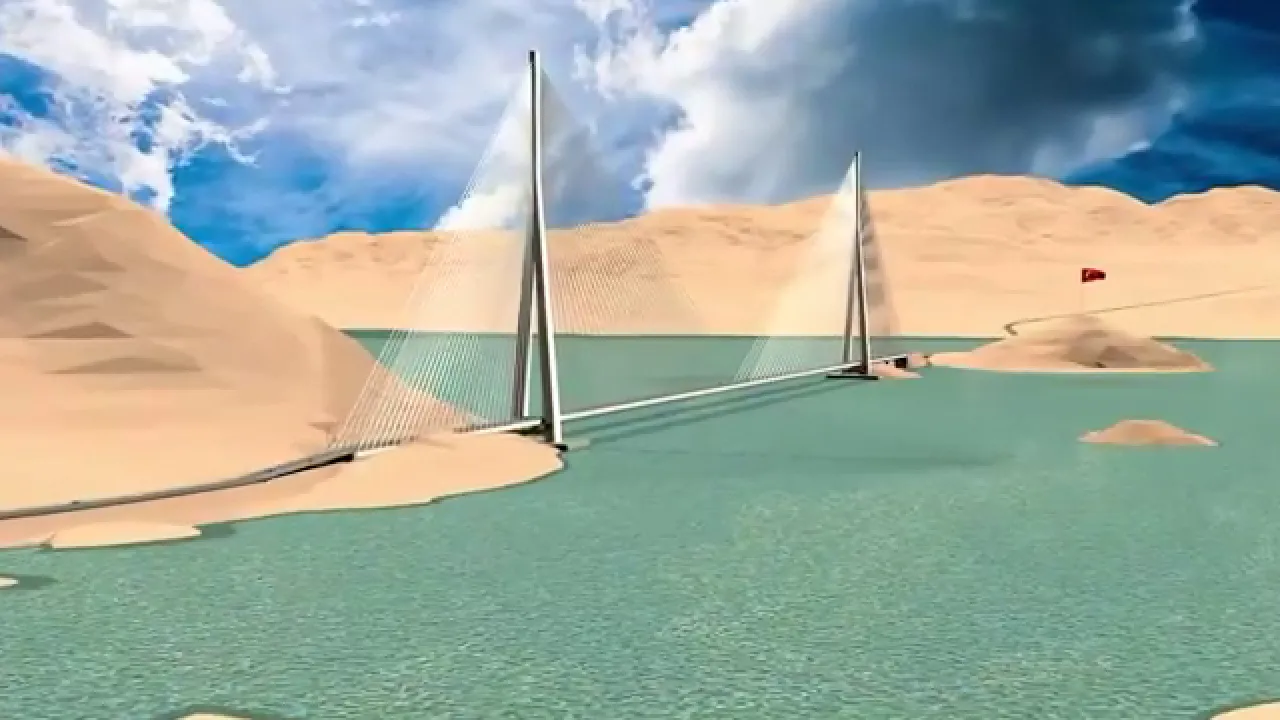

6. How does Sunko Proje approach the design of cable-stayed versus suspension bridges?

Cable-stayed and suspension bridges each present unique design challenges. Cable-stayed bridges, with their direct cable-to-pylon connections, offer greater stiffness and reduced deck deformation, making them ideal for moderate spans. Suspension bridges, preferred for longer spans, are more flexible but require careful consideration of deflection. Our design approach at Sunko Proje A.Ş. is tailored to the specific needs of each project, balancing structural integrity, aesthetics, and functionality.

7. How does Sunko Proje determine the optimal pylon height and cable arrangement in a cable-stayed bridge?

Determining the optimal pylon height and cable arrangement involves an iterative design process at Sunko Proje A.Ş. Typically, the pylon height is about 1/5th to 1/7th of the main span length, providing the necessary leverage for the cables. We explore different cable arrangements, such as radial, harp, or fan patterns, using FEA to model their impact on structural performance. This ensures minimal deflection and optimal load transfer, resulting in a bridge that is both structurally sound and aesthetically pleasing.

8. What challenges does Sunko Proje face when designing bridges with significant skew angles or curvature?

Designing bridges with significant skew angles or curvature introduces challenges such as uneven load distribution and increased torsional effects. At Sunko Proje, we address these challenges with detailed 3D FEA, ensuring that the effects of skew and curvature are accurately captured. Additional diaphragms or cross-frames may be incorporated to enhance stiffness, and special bearings are designed to accommodate the resulting movements, ensuring that the bridge remains stable and secure.

9. Why is redundancy important in bridge design, and how does Sunko Proje ensure it?

Redundancy is a key principle in bridge design, ensuring that if one element fails, others can carry the load, preventing a catastrophic collapse. At Sunko Proje, we incorporate multiple load paths and design critical elements with higher safety factors. For instance, we often use continuous spans and add extra cables in cable-stayed bridges. Regular inspections and maintenance are also critical to maintaining the redundancy and overall safety of the structure.

10. How does Sunko Proje A.Ş. design expansion joints and bearings to ensure a bridge’s performance and durability?

Expansion joints and bearings are crucial for accommodating movements caused by temperature changes, traffic loads, and seismic activity. At Sunko Proje A.Ş, we carefully consider the expected range of movement, load-carrying capacity, and durability when selecting and designing these components. This ensures that the bridge can handle various stresses without compromising its structural integrity, contributing to the bridge’s long-term performance and durability.

Why Choose Sunko Proje A.Ş.?

Sunko Proje is committed to delivering bridge designs that stand the test of time. Our expertise, combined with cutting-edge technology and a deep understanding of structural engineering, ensures that every bridge we design is a masterpiece of innovation and precision. If you have a challenging bridge project, we’re ready to bring your vision to life.